You can use either way of connecting to create higher or lower voltages.

If the measured voltage is the difference of the two windings' voltages then you have connected start with start. If the voltage is higher than 19V (still working with my example) then you have connected the start of one winding to the end of the other. Connect A to E and measure between B and F. You can do something similar with the third winding. You can connect the windings this way to double the voltage or swap C and D to have the windings in phase again. If the voltage measured between B and D was 38V the windings are in anti-phase: if A is the start of A-B then C is the end of C-D. If the voltages are equal you can place them in parallel to double the current. If this is 0V (very low anyway) A-B and C-D are in phase, so if A is the "start" of A-B, then C is the "start" of C-D. Now connect A to C and measure the voltage between B and D. In my example rated voltages might be 2 x 12V and 8V. Those are unloaded voltages, and especially for toroidal transformers those may be much higher than the rated voltage.

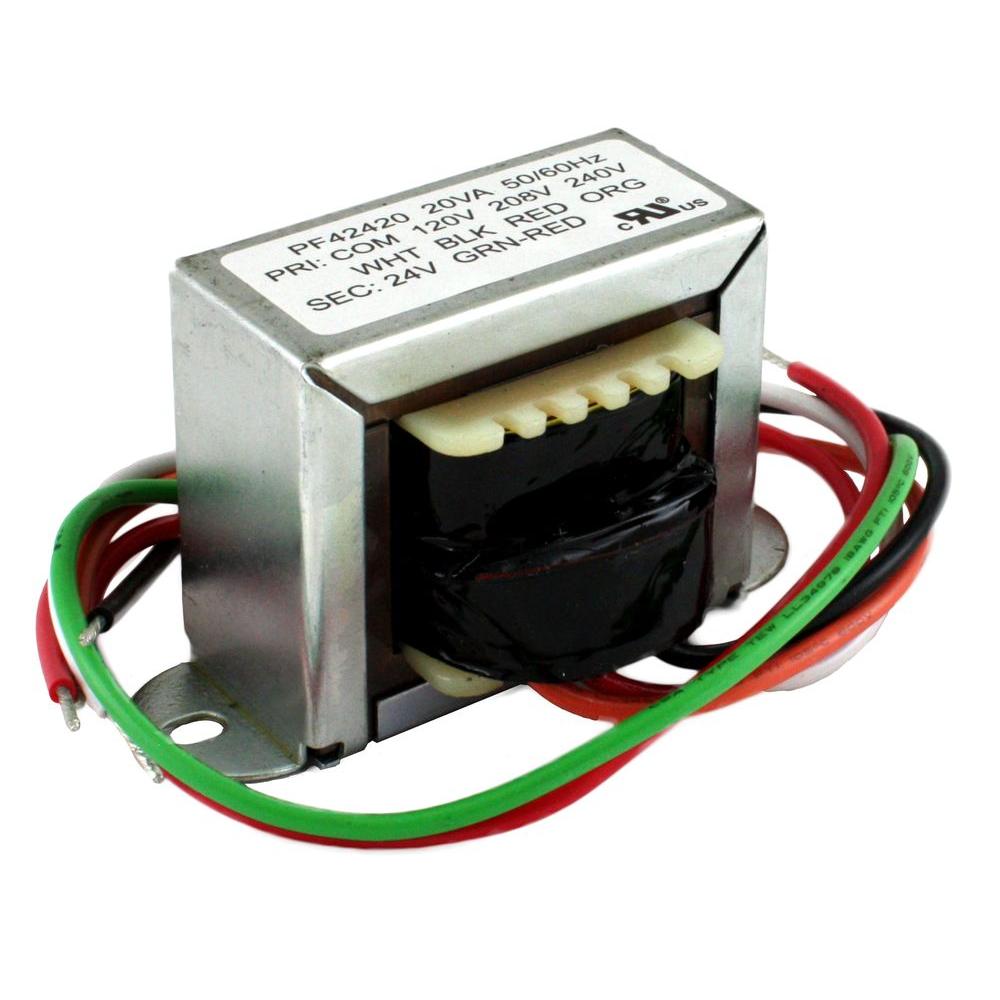

Measure the AC voltages of A-B, C-D and E-F. To find the polarity you'll have the connect the primary to the mains. Transformer windings have a phase relationship, but its typically not important for power supplies. If 4 or more wires have continuity, then you have a multi-tap transformer winding. Let's say you can find windings A-B, C-D and E-F this way. If 3 wires have continuity, then you probably have a center-tap winding (+, 0, -) If only 2 wires have continuity, then that is a simple winding. If you measure mega-ohms your measuring on two isolated windings. Depending on the transformer's rating you'll measure a few hundred ohms between begin and end of a winding. To find start and end of a winding you measure resistance with your multimeter. For the secondaries I presume they're separated. 1-48 of 515 results for '240v to 24v transformer' Results Overall Pick Control Transformer 40VA, Primary 120, 208, 240V Secondary 24V, HVAC Furnace Transformer Multi Tap (1 Pack) 1,028 300+ bought in past month STypical: 21. Grab the schematic, and start isolating and testing each component individually.The primary's wire is thinner and as W5VO says has a higher resistance. If the transformer itself is receiving 120V power but there is no voltage between the two low voltage output screws, then it is not working. If nothing looks bad, it's time to start poking around with a meter. with power to the transformer 'on', using the VOM on a low voltage scale (say 0-24VAC ) check for voltage between the two screw terminals. Using an inline fuse, this method might only cost one or two fuses. If you have a thermal imaging camera (not likely), you could look for hot spots when the equipment is powered up. Look for things that are out of place, especially things that might be shorted to the chassis or other grounded items. Start by visually inspecting all the low voltage components (relays, circuit boards, limit switches, etc.), looking for obvious signs of damage (broken, burnt, discolored, etc.). Turn the power off to the equipment at the breaker or serviceman switch, and insure it's off before poking around in the equipment. Rather than burning up more transformers, and/or blowing through a crate of fuses, why not try troubleshooting the circuit with the power off. This is likely caused by a damaged component within the control circuit, which is drawing far too much current for the transformer. As others have mentioned, the transformer is burning up because the load on it is too great.

0 kommentar(er)

0 kommentar(er)